Introduction

MRH is ISO 9001:14001 certified and a leading manufacturer of textile reinforced Conveyor Belt in India for use in virtually every sector where material handing is carried out on Conveyor Belt.

We have installed latest Machinery and have fully equipped laboratory for testing Raw Materials and Finished Products. The Conveyor Belts are manufactured under supervision of experienced and qualified technical staff as per our quality plan. Our quality control team ensures strict compliance of the required specifications during each stage of production.

MRH enjoys good reputation as a reliable and dependable manufacturer of Conveyor Belt. This has been possible because of high quality standards maintained and followed at every stage of manufacturing process.

MRH is committed to meet the delivery requirements of the customers who can rely upon us for their Critical and Regular requirements to be met in the shortest possible time.

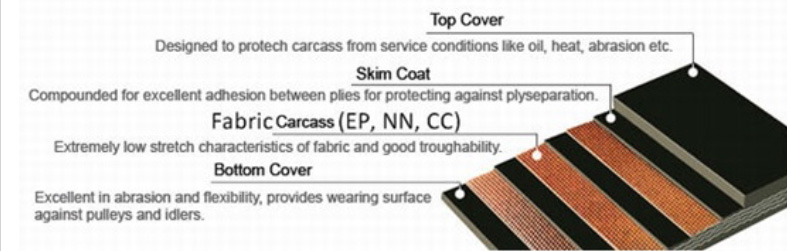

Belt Construction

Textile/Fabric Reinforced Conveyor Belts are generally composed of the following components:

RUBBER COVER(TOP)

It protects the carcass mainly from impact damage, wear, cut, gauge caused by the material conveyed. It also protects the strength member from effect of oil, heat, flame, chemicals etc. as the case may be.

SKIM COATING

It protects fabric layers against chaffing by separating them and also provides adequate bonding between different layers of fabric. Provides certain amount of load support and cushioning effect to impact on loading.

CARCASS

It provides the tensile strength and body necessary to move the loaded belt. The carcass is made of a rubberized fabric plies bonded together, such as, cotton-cotton, cotton-nylon, nylon- nylon and polyester-nylon fabrics

RUBBER COVER(BOTTOM)

It provides good coefficient of friction between the belt and the pulley. Also helps protect the carcass from wear and impact damage from the idlers during carriage of the material and from the material accumulated on the idlers.

BREAKER

Breaker fabric is recommended for applications involving high impact of material on the conveyor belt. It helps protect the carcass from the impact damage. Due to its weaving nature the breaker disburses impact force in different directions thereby resisting the effect of impact force at a particular point thus saving the carcass from impact damage.

MRH Range Of Nylon-Nylon & Polyester-Nylon Belting

| BELT WIDTH | 200 mm To 2400 mm |

|---|---|

| NO.OF PLIES | 1 TO 7 |

| EDGE | Molded/Protected Edge, Cut |

| BREAKER | Top, Bottom, Floating, Edge |

| TYPE OF BREAKER | Nylon, Polyester |

| LENGTH | Standard roll length is 200 meters. However, tailor-made lengths as per specific requirements can be produced. The restriction on length over and above 200 meters is subject to transportable roll diameter and weight. |

| BELT THICKNESS | 3mm TO 40mm |

| DUTY OF BELTING | Type I,II and III |

| COVER GRADES | M-24, N-17, M-25, SAR-120, SAR-90, SAR-60, OR,FR,HR/HR-T1, SHR/HRT-2, HR-T3(150°C),EPDM(220°C), Hygienic(Food Grade), OR-HR |

| STANDARDS FOLLOWED | IS1891 (Parts I,II,III,IV&V), BS490, CAN-CSA-M422-M87-C, ISO-340, ISO4195(I&II), AS1332, DI-22102 |

Specially designed fabrics with suitable inter-ply/skim rubber are used to withstand impact on belts which is a common cause for belt damage. These belts are manufactured for achieving high splice strength, either hot or cold method with standard system of splicing.

Belting Technical Data

ALL NYLON-NYLON (NN) & POLYSTER-NYLON (EP) BELTING TECTNICAL DATA

BELT DESIGNATION

MAX. RECOMMENDED WORKING TENTION(VULCANIS ED SPLICE)

NORMAL CARCASS THICKNESS

NOMINAL CARCASS WEIGHT

MIN.BELT WIDTH FOR SATISFACTORY TROUGHING (mm)

MAX.BELT WIDTH(mm) FOR SATISFACTORY LOAD SUPPORT MATERIAL DENSITY(T/M³)

| NN | EP | NN | EP | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Type | Rating | (KN/m) | mm | mm | (k g/m2) | (k g/m2) | 35° | 45° | Upto 1.0 | Upto 1.5 | Upto 2.5 |

| TYPE - II | 250/2 | 25 | 2.4 | 2.6 | 2.4 | 2.5 | 500 | 600 | 650 | 600 | 450 |

| 315/2 | 31.5 | 2.5 | 2.7 | 2.5 | 2.6 | 500 | 600 | 1000 | 800 | 650 | |

| 400/2 | 40 | 2.8 | 3 | 2.5 | 2.7 | 500 | 600 | 1000 | 800 | 650 | |

| 315/3 | 31.5 | 2.7 | 2.9 | 3.1 | 3.1 | 500 | 600 | 1200 | 1000 | 800 | |

| 400/3 | 40 | 3 | 3.2 | 3.2 | 3.4 | 500 | 600 | 1200 | 1050 | 900 | |

| 500/3 | 50 | 3.3 | 3.5 | 3.4 | 3.5 | 500 | 600 | 1400 | 1200 | 900 | |

| 630/3 | 63 | 3.4 | 3.6 | 3.5 | 4.1 | 600 | 650 | 1400 | 1200 | 1050 | |

| 400/3 | 40 | 3.3 | 3.6 | 4.4 | 4.3 | 500 | 600 | 1200 | 1050 | 900 | |

| 500/3 | 55 | 3.8 | 4.2 | 4.5 | 4.8 | 500 | 600 | 1400 | 1200 | 900 | |

| TYPE-III | 315/3 | 31.5 | 3 | 3.3 | 3.6 | 3.5 | 500 | 600 | 1200 | 1000 | 800 |

| 400/3 | 40 | 3.2 | 3.5 | 3.6 | 3.8 | 500 | 600 | 1200 | 1050 | 900 | |

| 500/3 | 50 | 3.6 | 4.1 | 3.9 | 4 | 500 | 600 | 1400 | 1200 | 900 | |

| 630/3 | 63 | 3.7 | 4.3 | 4 | 4.5 | 600 | 650 | 1400 | 1200 | 1050 | |

| 500/4 | 55 | 4.2 | 4.6 | 5.1 | 5.4 | 500 | 600 | 1400 | 1200 | 900 | |

| 630/4 | 70 | 4.7 | 5.4 | 5.3 | 5.6 | 600 | 650 | 1600 | 1400 | 1200 | |

| 800/4 | 90 | 5.1 | 5.8 | 5.6 | 6.3 | 650 | 800 | 1800 | 1600 | 1400 | |

| 1000/4 | 110 | 5.4 | 6.6 | 6.6 | 7.7 | 650 | 800 | 1800 | 1600 | 1400 | |

| 1250/4 | 140 | 6 | 7.2 | 7.2 | 8.2 | 800 | 1000 | 2000 | 1800 | 1600 | |

| 1400/4 | 160 | 6.4 | 7.8 | 7.7 | 9.1 | 1000 | 1200 | 2000 | 1800 | 1800 | |

| 100/4 | 180 | 7.4 | 8.8 | 8.2 | 9.9 | 800 | 1050 | 2000 | 2000 | 2000 | |

| 2000/4 | 220 | X | 11.4 | X | 12.4 | 1050 | 1200 | 2000 | 2000 | 2000 | |

| 800/5 | 90 | 5.6 | 6.4 | 7.1 | 7.2 | 750 | 800 | 1800 | 1600 | 1400 | |

| 1000/5 | 110 | 5.9 | 7 | 8.1 | 8.1 | 800 | 1000 | 2000 | 1600 | 1400 | |

| 1250/5 | 140 | 6.4 | 8.1 | 9.9 | 9.9 | 900 | 1050 | 2000 | 1800 | 1800 | |

| 1400/5 | 160 | 6.9 | 8.6 | 10.2 | 10.2 | 1000 | 1200 | 2000 | 1800 | 1800 | |

| 1600/5 | 180 | 7.2 | 9 | 10.5 | 10.5 | 1000 | 1200 | 2200 | 2000 | 2000 | |

| 2000/5 | 220 | 9 | 11.2 | 12.6 | 12.6 | 1050 | 1200 | 2400 | 2200 | 2000 | |

| 2500/5 | 280 | X | 14 | 15.8 | 15.8 | 1050 | 1200 | 2400 | 2400 | 2200 |

Belt Cover Grades & its Application

STANDARD & COVER GRADES

TENSILE STRENGTH (Mpa) MIN.

%ELONGATION AT BREAK(MIN.)

ABRASSION LOSS(mm³) MAX.

APPLICATION

| GENERAL PURPOSE | |||||

|---|---|---|---|---|---|

| DIN | X | 25 | 450 | 120 | Rubber covers for general purpose of

belting are specially compounded from

natural rubbers of finest quality which

provides the cover exceptional

toughness and outstanding resistance

to cut, tear, gauging & abrasion in the

ultimate aggressive environment. It sis

the ideal for conveying ores of all

kinds, rocks, granite, quartz and other

heavy sharp-edged and abrasive

material whether run of

mine(ROM),quarried or primary

crushed. The temperature of material being carried should not exceed 70˚C |

| BS | M24 | 24 | 450 | 150 | |

| SABS | M | 24 | 450 | 120 | |

| AS | M | 24 | 450 | 125 | |

| IS | M24 | 24 | 450 | 150 | |

| NERP | SAR | 24 | 450 | 120 | |

| DIN | Y | 20 | 400 | 150 | |

| AS | A | 17 | 400 | 70 | |

| DIN | W | 18 | 400 | 90 | |

| RMA | 1 | 18 | 450 | 150 | |

| AS | N | 17 | 400 | 200 | |

| BS | N17 | 17 | 400 | 200 | |

| IS | N17 | 17 | 400 | 200 | |

| IS | N17(S) | 17 | 400 | 150 | |

| SABS | N | 17 | 400 | 150 | |

| RMA | 2 | 14 | 400 | 200 | |

| HEAT RESISTANT | Suitable for carrying Hot materials like Sintered , Ore, Coal, Sinter, Cement, Clinker, Dry Hot Limestone | ||||

|---|---|---|---|---|---|

| IS | T1 | 12.5 | 350 | 180 | Suitable for material temperature Lump/Predominance of lump:125˚C(Max.) Fines (powdered materials)predominance of fines:100˚C(Max.) |

| IS | T2 | 12.5 | 350 | 170 | Suitable for material temperature Lump/Predominance of lump:150˚C(Max.) Fines (powdered materials)predominance of fines:125˚C(Max.) |

| NERP | T3 | 12.5 | 400 | 180 | Suitable for material temperature up to 150˚C |

| NERP | SSHR | 10.0 | 400 | 200 | Suitable for continuous material temperature 220˚C and intermitted 300˚C |

| FIRE RESISTANT | Fine prone materials/applications/installations necessitate use of

fire resistant grade conveyor belting, fire resistant grade belts are

used to carry coal, Lignite in Thermal Power stations and where

there are chances of fire. All grades of FR Belts have antistatic property and passes drum friction test as per relevant standard. |

|||||

|---|---|---|---|---|---|---|

| C AN-C S A-C- M422-M87(C) | FR | 17 | 350 | 200 | ||

| IS | FR | 17 | 350 | 175 | ||

| IS O-340 (With Cov) | FR | 17 | 350 | 175 | ||

| DIN/NF | FR | 15 | 350 | 175 | ||

| AS | FR | 14 | 300 | 175 | ||

| JIS | FR | 14 | 300 | 175 | ||

| MSHA | FR | 14 | 300 | 175 | ||

| OIL & CHEMICAL RESISTANT | Applicable for carrying fertilizers, Oil sprayed coke etc. where swelling of cover is a problem due to Oil, Fuel contamination | ||||

|---|---|---|---|---|---|

| IS | OR | 12 | 250 | 180 | |

| NERP | OR-HR | 12 | 300 | 180 | Suitable for application mentioned above with hot material as mentioned above up to 100˚C |

| OZONE & U-V RESISTANT | Suitable for environment where high ozone concentration generates cracks on the belt surface. Belts are also having U-V Resistant cover. | |||

|---|---|---|---|---|

| AS | 24 | 450 | 150 | |

High Heat Resistant Grade (HHR)

With our strong commitment towards R&D we have developed HHR Conveyor Belts.

The HHR Belt has been specially designed to overcome the deficiencies of Conventional H.R. . Super H.R., UHR Grade Belts, such as less belt life, crack formation in cover, Ballooning of belt etc., resulting in high belt consumptions, high inventory, uncertain & frequent change-over, high spillage etc., resulting in increase in belt costs.

SPECIAL AREAS OF APPLICATION

HHR belts avoid huge losses on account of high belt consumption, overcome un-certainties on belt/joint failure and reduce pollution by containing/stopped spillages, which are caused due to material entrapment in cracks etc.

Very hot lumpy as well as powdery material handling/conveying, e.g. clinker, sinter, burnt lime etc., where the material temp. is above 150°C, with occasional Red Hot material.

HHR is a speciality product for high heat application, hence is advised that customer should provide maximum critical information on application, enabling us to recommend suitable belt construction, if required.

Breaker fabric is recommended for applications involving high impact of material on the conveyor belt. It helps protect the carcass from the impact damage. Due to its weaving nature the breaker disburses impact force in different directions thereby resisting the effect of impact force at a particular point thus saving the carcass from impact damage.

Salient Features of HHR

(High Heat Resistant) grade

- Crack free covers

- Elastic (Rubber cover elongation at break 400 %min.)

- High heat resistance application

- Rugged construction

- Special polymer compound with a unique high heat sustenance quality

- Remarkably high bond strength under high heat flex-fatigue conditions.

- Specially designed fabrics to take care of flex fatigue at high temp.

| For continuous load | 220°C |

|---|---|

| For intermittent load Occasional red hot material on normal pile |

up to 300°C |

Minimum Pulley Diameters for the Belt Conveyors

| CARCASS THICKNESS(mm) | RECOMMENDED MINIMUM PULLEY DIAMETRE(mm) | |||||||||||||

| Reinforcement Material | Percentage of “RMBT” used | |||||||||||||

| Cotton/Cotton | Nylon/Nylon | Polyester/Nylon | Over 60% Up to 100% |

Over 30% Up to 60% |

Up to 30% | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TYPE OF PULLEY | ||||||||||||||

| From | To | From | To | From | To | A | B | C | A | B | C | A | B | C |

| - | 1.2 | - | 1.1 | - | 0.9 | 100 | - | - | - | - | - | - | - | - |

| 1.3 | 1.5 | 1.2 | 1.3 | 1.0 | 1.1 | 125 | 100 | - | 100 | - | - | - | - | - |

| 1.6 | 2.0 | 1.4 | 1.7 | 1.2 | 1.7 | 160 | 125 | 100 | 125 | 100 | - | 125 | 100 | - |

| 2.1 | 2.5 | 1.8 | 2.2 | 1.5 | 1.8 | 200 | 160 | 125 | 160 | 125 | 100 | 125 | 125 | 100 |

| 2.6 | 3.1 | 2.3 | 2.7 | 1.9 | 2.3 | 250 | 200 | 260 | 200 | 160 | 125 | 160 | 160 | 125 |

| 3.2 | 3.9 | 2.8 | 3.5 | 2.4 | 2.9 | 315 | 250 | 200 | 250 | 200 | 160 | 200 | 200 | 60 |

| 4.0 | 5.0 | 3.6 | 4.4 | 3.0 | 3.7 | 400 | 315 | 250 | 315 | 250 | 200 | 250 | 250 | 200 |

| 5.1 | 6.2 | 4.5 | 5.5 | 3.8 | 4.6 | 500 | 400 | 315 | 400 | 315 | 250 | 315 | 315 | 250 |

| 6.3 | 7.8 | 5.6 | 7.0 | 4.7 | 5.8 | 630 | 500 | 400 | 500 | 400 | 315 | 400 | 400 | 315 |

| 7.9 | 10.0 | 7.1 | 8.8 | 5.9 | 7.4 | 800 | 630 | 500 | 630 | 500 | 400 | 500 | 500 | 400 |

| 10.1 | 12.5 | 8.9 | 11.1 | 7.5 | 9.2 | 1000 | 800 | 630 | 800 | 630 | 500 | 630 | 630 | 500 |

| 12.6 | 15.6 | 11.2 | 13.8 | 9.3 | 11.5 | 1250 | 1000 | 800 | 1000 | 800 | 630 | 800 | 800 | 630 |

| 15.7 | 17.5 | 13.9 | 15.5 | 11.6 | 12.9 | 1400 | 1250 | 1000 | 1250 | 1000 | 800 | 1000 | 1000 | 800 |

| 17.6 | 20.0 | 15.6 | 17.7 | 13.0 | 14.0 | 1600 | 1250 | 1000 | 1250 | 1000 | 800 | 1000 | 1000 | 800 |

| - | - | 17.8 | 20.0 | 14.9 | 16.6 | 1800 | 1400 | 1250 | 1400 | 1250 | 1000 | 1250 | 1250 | 1000 |

| - | - | - | - | 16.7 | 18.7 | 2000 | 1600 | 1250 | 1600 | 1250 | 1000 | 1250 | 1250 | 1000 |

*RMBT- Recommended Maximum Belt Tension

A. Driving pulley and pulleys exposed to high belt tension e.g. main driving pulley on the head or tail, delivery pullets under full tension, loop pulleys in the tripper, terminal head pulleys in the case of tail driving etc.

B. Snub pulleys in the return run under lower belt tension e.g. terminal tail pulleys in the case of head driving, terminal head pulleys for downhill conveying, if the terminal tail pulley is braked, snub and bend pulleys in the take-up devices.

C. Bend pulleys, for a change of direction of the belt of less than 30°

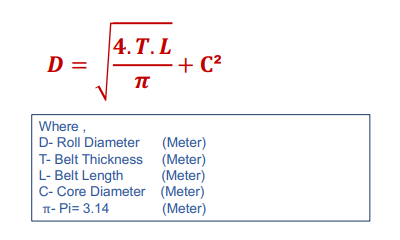

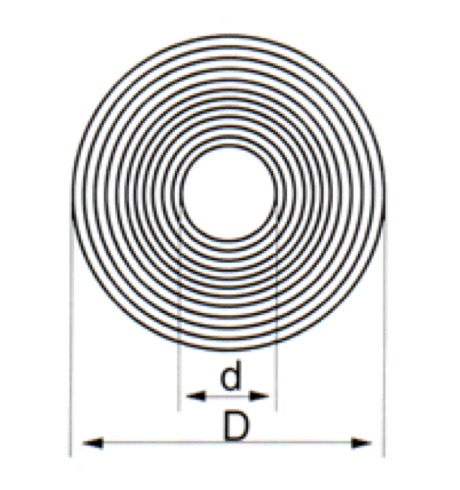

Calculation of Conveyor Belt Roll Diameter

1. Add 0.15 meter to the calculated approx. belt roll diameter to arrive at wooden drum diameter.

2. Keeping in view the stability of drum in transit and installation, it is suggested that drum-width to drum height/diameter should be maintain within the ratio of 13.5.

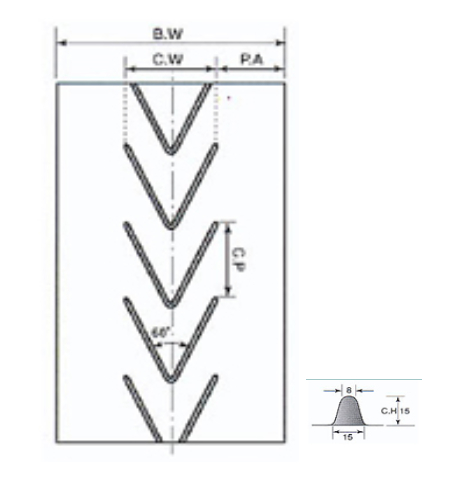

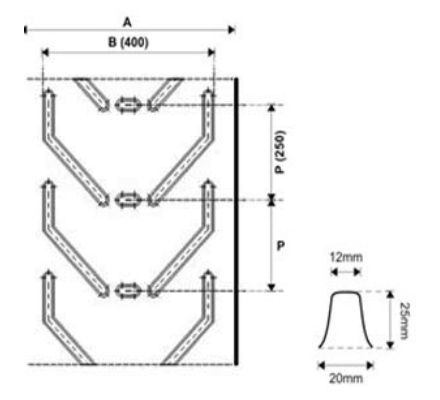

Chevron Conveyor Belts

Chevron Conveyor Belts are specially designed for the effective material handling in the applications where the angle of incline is higher (>18°) for the material to be conveyed and the the material tends to slide on a conventional conveyor belt. Chevron belts are suitable for transporting a wide range of bulk materials and also fir unit loads such as bags, bales, crates, sacks etc. Chevron achieve high conveying capacities even at inclinations of up to 40-45°.

In contrast to the profiles/cleats that are vulcanized separately on to the flat conveyor belt, the profiles/cleats on the Chevron Belt are integrally molded into the top cover of the belt during the manufacturing process. The advantage of specially designed integrally molded Chevron Belts is that the life of profile/cleat is enhanced due to low flexing/bending stress generated while negotiating around pulleys, this feature also permits the use of smaller pulley diameters.

The overlapping of the profiles/cleats assures a smooth return run and thus minimizing the damage caused, by the return idlers, to the profiles/cleats.

Incline angles achievable incline angles are dependent on the type of chevron selected and the material characteristics such as lump size, flow ability, dry/wet, shape etc.

Range Of Chevron Belts

| BELT WIDTH | 350 mm(14”) to 1600 mm(64”) |

|---|---|

| TYPE OF FABRIC | EP(Polyester-Nylon), NN/PP(Nylon-Nylon) |

| PROFILE/CLEAT HEIGHT | 15 mm, 25 mm, 30 mm |

| NO.OF PLIES | 1 to 5 |

| LENGTH | Standard roll length is 100 meters. However, tailor-made lengths as per specific requirements can be produced. The restriction on the length over and above 100 meters is subjected to transportable roll diameter and weight. |

| DUTY OFBELTING | Type I,II,III |

| COVER GRADES | M-24, N-17, M-25, SAR-120, SAR-90, SAR-60, OR,FR, HR/HR-T1, SHR/HR-T2, HR-T3(180C), Hygienic (Food Grade), OR-HR |

| STANDARDS FOLLOWED | IS1891 (Part I,II,III,IV,V),BS490,CAN-CSA-M422-M87-C, ISO-340, ISO4195(Part I &II), AS 1332,DIN 22102,RMA.SANS |

Chevron Conveyor Belts

Range of Chevron Belts

| Item Code | BELT WIDTH (D) mm | CLEAT WIDTH (B) mm | CLEAT PITCH (C) mm | CLEAT HEIGHT mm |

|---|---|---|---|---|

| NLYC 15-575 | 600 TO 1200 | 575 | 335 | 15 |

| Item Code | BELT WIDTH (D) mm | CLEAT WIDTH (B) mm | CLEAT PITCH (C) mm | CLEAT HEIGHT mm |

|---|---|---|---|---|

| NLVC 15-300 | 350 TO 650 | 300 | 145 | 15 |

| NLVC 15-385 | 400 TO 800 | 385 | 250 | 15 |

| NLVC 15-450 | 500 TO 800 | 450 | 220 | 15 |

| NLVC 15-600 | 750 TO 1000 | 600 | 250 | 15 |

| NLVC 15-750 | 900 TO 1200 | 750 | 250 | 15 |

| NLBHC | 1200-1600 | 1000 | 400 | 25 |

| Item Code | BELT WIDTH (D) mm | CLEAT WIDTH (B) mm | CLEAT PITCH (C) mm | CLEAT HEIGHT mm |

|---|---|---|---|---|

| NLBHC 25-450 | 500 TO 900 | 450 | 250 | 25 |

| NLBHC 25-550 | 600 TO 1000 | 550 | 250 | 25 |

| NLBHC 25-750 | 900 TO 1200 | 750 | 330 | 25 |

| NLYHC 30-1200 | 1400 TO 1600 | 1200 | 330 | 30 |

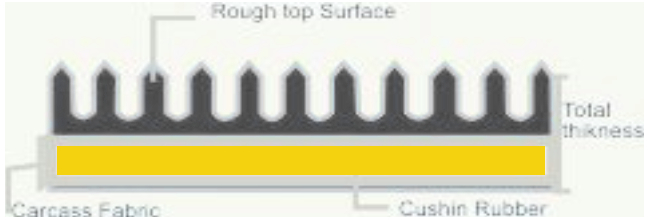

Rough Top Conveyor Belts

Rough Top Conveyor Belts

Rough Top Belts, are available with rough pattern on the carrying side of the belt, suitable

for transportation at inclined angles of light weight materials and packages that may otherwise roll

down easily.

The belts are manufactured, with the top surface having a rough pattern widths up to 1500 mm wide in

2 or 3 plies with different rubber cover grades. The belts can be supplied with open ends as well as in

endless lengths depending on the application.

These belts are provided with cushioning and anti-slippery or anti-skid effects. Due to its coarse and soft rugged surface pattern on the top cover it gives high friction between belt and the carried load. It is suitable for transporting fragile or deform-able materials packed in bags and cartons in inclined application. These type of belts are also called as Wavy top belts.

We will solve your rough top conveyor belting challenges across applications, including package, sack, or box conveying on inclines or declines up to 35 degrees. Rough top conveyor belts cushion the load, absorbing vibrations and minimizing impacts.

Quality and Consistency

The quality starts with the procurement of best suited raw materials(preferably from origin/source), tested for compliance with strict internal quality norms. The stringent internal specifications are strictly adhered to at each stage of pre and post production to ensure precisely engineered finished final product. Check and re-checks are common in production stage to make sure that there is no deficiency left at ant stage.

Quality Assurance bases on thorough technical knowledge of belting designs and efficient conveyor operations, the green/ raw belts are built under equal ply tensioning, proper laying of piles and uniform thickness maintained under adequate pressure so that finished product performs in a consistently reliable manner on account of straight running and uniform load bearing of reinforcement member.

A FIVE LET OFF AUTOMATED BELT BUILDING MACHINE

A very good set up that ensures belt assembly with centering of piles under controlled uniform tension. The machine is also used for precise cutting/sitting of finished goods.

A WIDE RANGE OF BELT CURING PRESSES

Of widths ranging from 500 to 2500 mm wide and in a variety of lengths provide excellent belt consolidation of optimum cure apart from giving the case and flexibility quality belts efficiently.

ADVANCED FULLY COMPUTORISED UNIVERSAL TESTING MACHINE(UTM)

It is a versatile, fully computerized testing used for thickness tensile strength (FTTS), Elongation at reference load, Elongation at break, cyclic load testing etc.

RHEOMETER (ff)

It is used to predetermine processing safely. The testing gives details of compound’s important properties such as cure speed/ time, optimum cure time, viscosity, scorch time/ performance, reversion, cross linking time etc. All uncured compounds are subjected to (100%) cemetery inspection. Only after meeting the preset values, compounds are released to production department.

ABRASION TESTING MACHINE

Abrasion/ wear resistance being one of the most critical properties of conveyor/ elevator belting is tested on this machine as per DIN 53516.

DRUM FRICTION TESTING MACHINE

The machine is used for testing the fire resistant property of conveyor belt against friction. The machine is well equipped with load cell, temperature indicators, air circulation etc. aa per national and international standards.

SURFACE ELECTRICAL RESISTIVITY TESTING MACHINE

The machine tests the electrical resistively of a conveyor belt. The test is essential to determine the anti static property of a conveyor belt.

FLAME TEST APPARATUS

The apparatus is used for testing the flame-proof property of a conveyor belt.

AGEING OVENS

Equipped with digital temperature indicators, temperature controllers and plotters.

A FULLY EQUIPPED TEST LABORATORY AND R&D WING

All tests are conducted at our fully quipped state of the art test lab. The R&D wings helps in development and improvement of rubber compounds in line with latest standard/customer requirements. Latest achievements of our R&D are SSHR and MEGAHETA cover grade of belting of high heat resistant conveyor belt applications. Cement and Steel sectors in particular are the most beneficiary of its crack free properties.

MRH Engineered Rubber Products

| Works : | 26- 27 Warina industrial Complex, Kapurthala Road, Jalandhar City 144013, Punjab, INDIA |

|---|---|

| Tel : | +91-181-5147211, +91-181-5147212 |

| Email : | export@mahajantyre.com, info@mahajantyre.com |